Blocell, which produces high-standard equipment and automation systems to meet the quality requirements of the pharmaceutical industries and received awards from 4 different international organizations, continues to make a difference in its field. Mustafa Cüneyt Çıkman, Chief Executive Officer, Bloocell Technology, shared the origin story and goals of the company with our readers…

Could you inform us about yourself and the origin story of the Bloocell brand?

I am Mustafa Cüneyt ÇIKMAN, the founder of BLOOCELL. I received basic training in pharmacology, medicine, physiology, histology, biomechanics and anatomy engineering. I gained expertise in the development of Virtual Reality, Augmented Reality organ, tissue, cadaver modeling and training simulation systems. I have been a manager and executive in National and International projects including mechanics, mechatronics, chemistry, metallurgy, veterinary medicine, biomedical, electronic engineering.

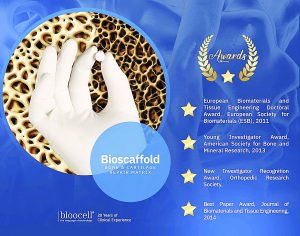

Bloocell® was my biggest dream. The project, which was realized with the contributions of valuable scientists of our country, has received awards from the American Academy of Orthopaedic Surgeons (AAOS), the Orthopaedic Research Society (ORS) and John Hopkins University and 4 different international organizations.

Bloocell Bioscaffold is the first “ARTIFICIAL BONE PROJECT” implemented in the world

In the current climate of increasing life expectancy with the increase in bone-related injuries, a paradigm shift is taking place from standard bone grafting to tissue engineering / tissue regeneration gain in applications such as orthopedic, dental, plastic and reconstructive surgery. Bloocell is the first representative of this paradigm in the world.

The scientists in the Bloocell Scientific Advisory Board at the Johns Hopkins University Faculty of Medicine Translational Tissue Engineering Center and Biomedical Engineering Department have been completed by obtaining all legal permissions and registration to the Medical Devices institution. “Bloocell Technology” from raw material to production was nationalized and its production was started by establishing a GMP (Good Manufacturing Practices) on-site production line within Life Sciences Institute, Boğaziçi University. The project, which is the first in the world, has been presented to the service of our country and humanity.

What are your product types?

The team of Bloocell ® engineers is conducting their research to design a technological platform for the production of scaffolds that will enable 3D (3D) bone tissue regeneration. Our products allow customization of precise shape and geometry. This approach is critical for the products to fully adapt to the anatomical structure. Bloocell Bioscaffold’s unique architecture is conducive to the infiltration of cells and blood vessels that play a key role in wound healing and tissue repair. Bloocell ® assists in the natural stages of bone healing.

Bloocell ® offered its technology developed products to the market. “BLOOCELL HYBRID” used in neurosurgery and craniofacial surgery consists of titanium and polymer materials.

“BLOOCELL BONE AND CARILAGE REPAIR MATRIX” used in Orthopedics, Maxillofacial Surgery, Otorhinolaryngology, Plastic Surgery and Neurosurgery is a biomaterial used in the repair of bone and cartilage defects. We produce with high standards of equipment and automation systems.

So, what are your most demanded products?

The indication area of Bloocell Bioscaffold is wide. It is an osteoconductive material, that is, when used as a scaffold or template, it can form bone on its surface, in channels, and into pores. Its important feature is that it has the best ability to imitate the bone in terms of biomechanics and molecular weight, so we call it artificial bone. Bloocell Bioscaffold has superior technology with its “structural adaptation” and “natural mechanical compensation” features.

The internal structure of the product imitates the texture. In this way, it allows the tissue to develop. Bloocell ® Bioscaffold, which can take the desired anatomical shape or have pre-prepared forms, is designed for the treatment of bone augmentation and deteriorated structures.

Bloocell ® Technology provides vascularized tissue formation by mimicking bone. Doctors began to use this innovation for their patients. Unrivaled technology is one of the first symbols of groundbreaking medical devices in medicine. The surface technology developed by using Mesh and Barrier models in the repair of neural defects increases tissue transmission.

Bloocell ® Bioscaffold takes the physiological cues of the tissue in response and generates the appropriate geometry within it in the long term. Due to its enzymatic structure, it is completely removed from the body after treatment.

What about your in vivo and in vitro studies? What distinguishes this work from others?

What about your in vivo and in vitro studies? What distinguishes this work from others?

The role of Bone Tissue Engineering in Regenerative Medicine has been the subject of significant research over the past two decades. Technological advances have improved orthopedic implants and surgical techniques for bone reconstruction. However, advances in surgical techniques to reconstruct bone have been limited by the scarcity of available autologous materials and donor site morbidity. Recent advances in biomaterials have provided attractive alternatives to bone grafting, expanding surgical options to restore the shape and function of injured bone.

Bioactive (second generation) biomaterials have been developed that are characterized by controlled action and reaction to the host tissue environment while exhibiting controlled chemical degradation and absorption between the regenerated tissue and the replacement tissue .

The next generation Bloocell Bioscaffold is designed to promote the regeneration of host tissues by combining tissue engineering and in situ tissue regeneration methods with a focus on new applications, not only osteoconductive but also osteoinductive.

Bloocell Bioscaffold will open up new possibilities for tissue regeneration and repair. It currently supports bone reconstruction to restore structural and functional integrity for complex skeletal defects of post-traumatic, degenerative, neoplastic, or congenital /developmental “origin”.

Engineering functional bone using combinations of cells, scaffolds and bioactive factors, Bloocell capable of exhibiting favorable biomimetic and mechanical properties It is an exemplary and unique technology for future development in the bioscaffold field.

In summary, it shows what we can expect from the next generation concept of bone regeneration, which makes this work superior to the others.

Could you inform us about your export and target markets?

We made our Turkey and World launch. We expanded our market in MEDICA, America CES, Arab Health fairs. Our primary goal is to have a permanent say in the market. To cooperate with leading health institutes and technology companies and to expand our sales network in order to contribute to the country’s economy and become a world brand.

How do you evaluate your own position in your sector at home and abroad? What are your current position, strengths and plans in this market?

It is known that the tissue engineering North American market is 35 billion dollars. Continuing hot sales in Turkey, MENA region and Europe, additionally establishing a representative office. Bloocell America was opened and Russia, Central Asia, Pacific, China and India markets were entered. Our goal is to be a reliable and permanent brand in the global market. Bloocell technology will be the first Unicorn company in the field of health in our country.